according to statistics, the oil and gas sector consumes most engineering services - it accounts for 71 percent of the turnover. Next, an electric power industry with 26 percent follows. The demand is also formed by metallurgy, mining, mechanical engineering and chemical industry, but their shares are much less.

"our state strives for technological sovereignty. A fairly large amount of complex equipment is now in operation, only in oil and gas companies - about 62 thousand units. It is high -tech and high -marine, its failure can lead to colossal. Losses, ”explains Alexander Tretyakov, director of operating activities of the Kronstadt engineering center. - “The active development of engineering in Russia began about three years ago. By the present day of the basics, it was time to move on to more complex products and the development of its own rulers, the development of service.”

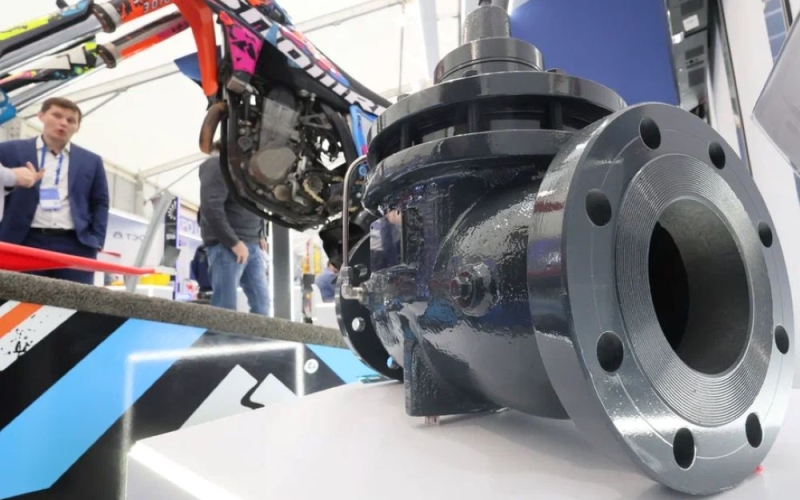

his company makes it independently and in cooperation of more than 2000 parts per month. They started with shut-off-regulating reinforcement, simple gaskets, flanges, gradually expanded competencies to overhaul of small turbines and compressomoat. And also came to the conclusion that it is necessary to launch 45 commodity positions that no one used to be in Russia: centrifugal pumps, gear, rifle, axial compressors, gate gaps for cracking, ball four -way cranes, etc. Moreover, this is not copying other people's products, but a new design development. So, at the exhibition in Tyumen, a crane model is presented, where the sludge from the walls is fet off with hot steam, plus the sludge with a special internal coating, so that its wear resistance increases by a third.

What is the role of the customer in engineering? According to Mikhail Ponomarev, a representative of the Sibur holding, a total of 220 names of critically important equipment in the federal level include the federal level.

"We perform three functions: we help to formulate technical tenders and provide access to the original object, provide the base order and the site for experimental and industrial tests. I can not help but note The contribution of the Institute of Oil and Gas Technological Initiatives (Inti) to this work in terms of synchronizing the needs of the industry and certification of new products, "Orit representative of petrochemistry.

"Daughter" Inti, "Unified Test Operator", has existed for two years. The head of this organization Sergei Gureev recalled the memorandum of the mutual recognition of the results of equipment testing: 10 large oil and gas structures joined him for a year.

"We coordinate methods, test volumes, program, invite the testing itself. It not only saves the manufacturers, but also provides quick circulation of products," notes the rapid circulation Expert.

company "ObTEK" - practically the same age as sanctions and participant in the Tyumen oil and gas cluster. She introduced a rotational feeder for an accurate dosage of bulk and granular components in petrochemistry. The product has foreign analogues, but it is more compact, hermetic, and the aluminum alloy of the case instead of cast iron and carbon steels provides it with lightness, corrosion resistance and minimal sticking of the material.

on the forum, the innovators not only demonstrated their achievements, but also shared their experience. In particular, the deputy director of the company Ekaterina Panfilova PerIt was eaten by the difficulties that you have to deal with the reverse engineering in the oil and gas industry. Firstly, most employees of the FIE enterprises are not ready for the specifics of such projects, and this is not just the purchase of spare parts, just the organization of measurements and 3D scanning is a separate serious issue. The goals of the customer and the contractor are different: the first seeks to close the current needs, for example, to make one shaft, and for the second piece production is often unprofitable. The third difficulty is pricing. The consumer wants to immediately hear the figure "for everything", but how to do it without drawings? As a result, the figure is either overestimated, or the supplier works as a minus or, worse, saves on materials.

however, Panfilov is sure of the efficiency of services: due to the consolidation of the needs of companies operating the same or similar equipment, and preliminary supplies - this is reduced by the cost of development and will allow the cost of the cost of developing Farm.